Unveiling the Excellence of Stainless Steel Spargers: Enhancing Efficiency and Quality

Introduction:

Stainless steel spargers have revolutionized numerous industries by providing an efficient and reliable solution for gas-liquid mixing processes. From pharmaceutical manufacturing to brewing, these ingenious devices play a pivotal role in optimizing production, improving product quality, and reducing operational costs. In this article, we delve into the world of stainless steel spargers, exploring their key features, applications, and the benefits they offer to various industries.

I. Understanding Stainless Steel Spargers

1.1 What is a Stainless Steel Sparger?

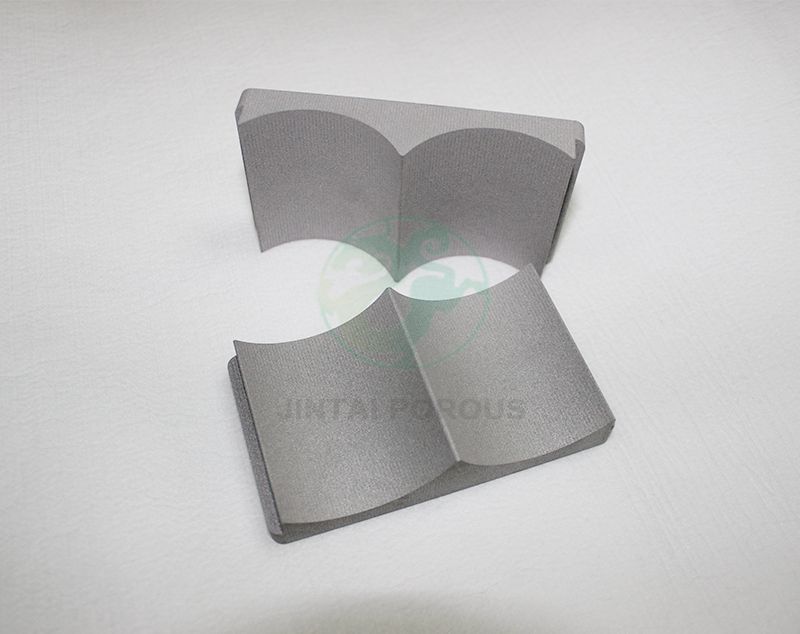

Stainless steel spargers are specialized devices designed to introduce gas (such as air or oxygen) into a liquid solution, creating a controlled environment for chemical reactions or enhancing physical processes. These spargers are typically crafted from high-quality stainless steel due to its exceptional durability, corrosion resistance, and hygienic properties.

1.2 How Do Stainless Steel Spargers Work?

Stainless steel spargers operate on the principle of bubble column reactors, where gas bubbles are dispersed evenly throughout the liquid medium. By diffusing gas bubbles into the liquid, spargers maximize the surface area for gas-liquid interaction, facilitating efficient mass transfer and reaction kinetics.

II. Applications of Stainless Steel Spargers

2.1 Pharmaceutical Industry

In pharmaceutical manufacturing, stainless steel spargers are employed in bioreactors and fermentation processes. They provide a controlled environment for the growth of microorganisms, such as bacteria or yeast, ensuring optimal oxygen transfer and nutrient distribution. This enhances cell growth and productivity while maintaining the integrity of the final product.

2.2 Food and Beverage Industry

Stainless steel spargers find extensive use in the food and beverage industry, particularly in the production of beverages like beer, carbonated drinks, and sparkling wine. By precisely infusing gases like carbon dioxide into the liquid medium, spargers create the desired effervescence, taste, and texture.

2.3 Water Treatment and Environmental Applications

The versatility of stainless steel spargers extends to water treatment plants, where they facilitate the transfer of dissolved gases, such as oxygen or ozone, into water. This helps in purifying the water by removing impurities and improving its overall quality. Additionally, spargers aid in wastewater treatment processes, where they assist in aeration and the removal of harmful pollutants.

III. Advantages of Stainless Steel Spargers

3.1 Durability and Corrosion Resistance

One of the key advantages of stainless steel spargers is their exceptional durability and resistance to corrosion. The stainless steel construction ensures a long lifespan, even in harsh operating conditions, making them a cost-effective investment for industries.

3.2 Hygienic Design

Stainless steel spargers are inherently hygienic, making them suitable for applications in sensitive industries like pharmaceuticals and food processing. The smooth surface of stainless steel minimizes the risk of contamination and allows for easy cleaning and sterilization.

3.3 Customization Options

Manufacturers offer a wide range of customization options for stainless steel spargers, allowing them to be tailored to specific applications. Variations in pore size, bubble size, and distribution patterns enable users to optimize gas-liquid interactions based on their unique requirements.

IV. Conclusion

In conclusion, stainless steel spargers have become indispensable tools across various industries, significantly improving production efficiency, product quality, and overall process performance. Their durability, hygienic design, and customization options make them an ideal choice for gas-liquid mixing applications. As industries continue to evolve and demand greater efficiency, stainless steel spargers will remain at the forefront, enabling innovation and progress.