Benefits and Applications of Conveyor LBP Chain

Conveyor LBP chains are crucial for enhancing material handling efficiency across various sectors. According to search results from Google, these specialized chains not only minimize back pressure but also facilitate the smooth transport of goods at high speeds, thereby improving overall operational workflows.

Key Features of Conveyor LBP Chain

Low Back Pressure Technology

The LBP chain significantly reduces friction among transported products. This characteristic is vital in preventing damage and ensuring smooth operations.

Durable Construction

Constructed from high-quality materials, LBP chains can handle heavy loads and endure wear and tear, ensuring long-term use.

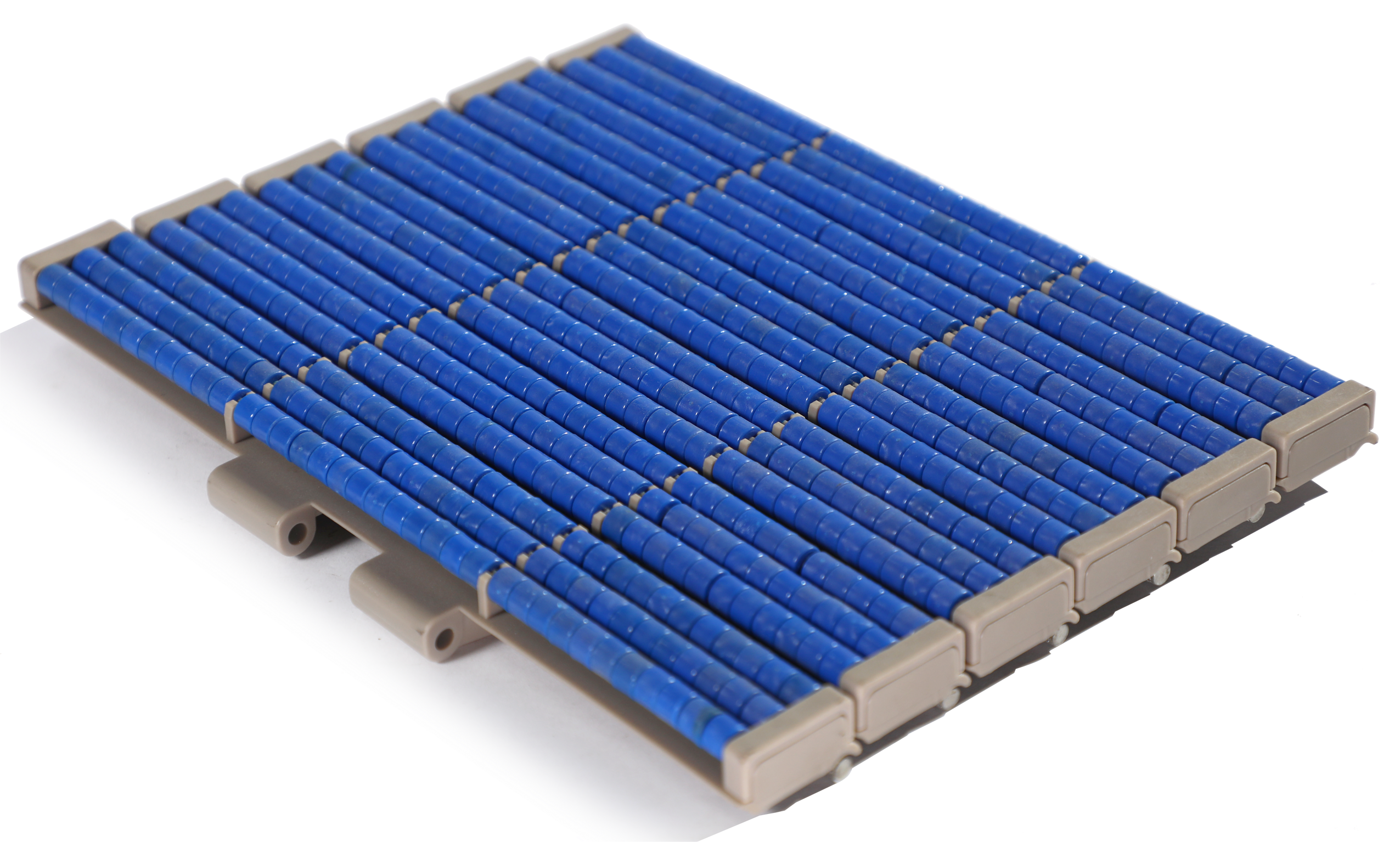

Modular Design

Thanks to their modular structure, LBP chains can be easily customized and integrated into existing conveyor systems.

Enhanced Product Stability

These chains are designed to maximize stability, effectively preventing products from tipping or shifting during transport.

Applications of Conveyor LBP Chain

Food and Beverage Industry

In the food and beverage sector, LBP chains are essential for the seamless movement of bottles, cans, and other products, which helps minimize downtime and boosts productivity.

Pharmaceutical Industry

These chains are particularly suited for transporting delicate items in pharmaceutical manufacturing, ensuring precision and care throughout the handling process.

Additional reading:4 Advice to Choose a Custom Bolt Manufacturer

Automotive Industry

LBP chains enhance the movement of components along automotive assembly lines, optimizing overall efficiency while maintaining workflow consistency.

Packaging Industry

They are ideal for packing lines, allowing for the smooth transport of boxes and cartons without risking product damage.

Benefits of Using Conveyor LBP Chain

Reduced Maintenance Costs

The robust design of Radius LBP chains minimizes wear and tear, thereby decreasing the frequency of maintenance and replacements.

Improved Operational Efficiency

With low back pressure and enhanced stability, LBP chains provide smoother workflows and quicker processing times.

Versatile Applications

These chains can adapt seamlessly to a wide range of operational requirements, from food processing to heavy industries.

Product Safety

By minimizing back pressure, LBP chains protect products from damage, maintaining high-quality standards.

Conclusion

Conveyor LBP chains are indispensable for effective material handling across various industries. Their advanced features, durability, and adaptability make them a worthwhile investment for boosting productivity and ensuring product safety. Incorporating LBP chains into your operation will lead to smoother workflows and increased efficiency.